Choosing a generic candle container can hurt your brand’s uniqueness. Without proper customization, your products won’t clearly stand out or appeal to buyers.

Customizing high-end candle containers involves clear steps from concept to final product, careful partner selection, understanding MOQ impacts, and strict quality control. Following these steps clearly ensures attractive, consistent, and successful products.

I recently guided a brand through their first customization project. Clearly following these steps helped them launch a successful product line. Let’s explore the process together.

What Are the Steps Involved in Customizing a Candle Container from Concept to Completion?

Maybe you’re unclear about the customization process. Let me explain it clearly.

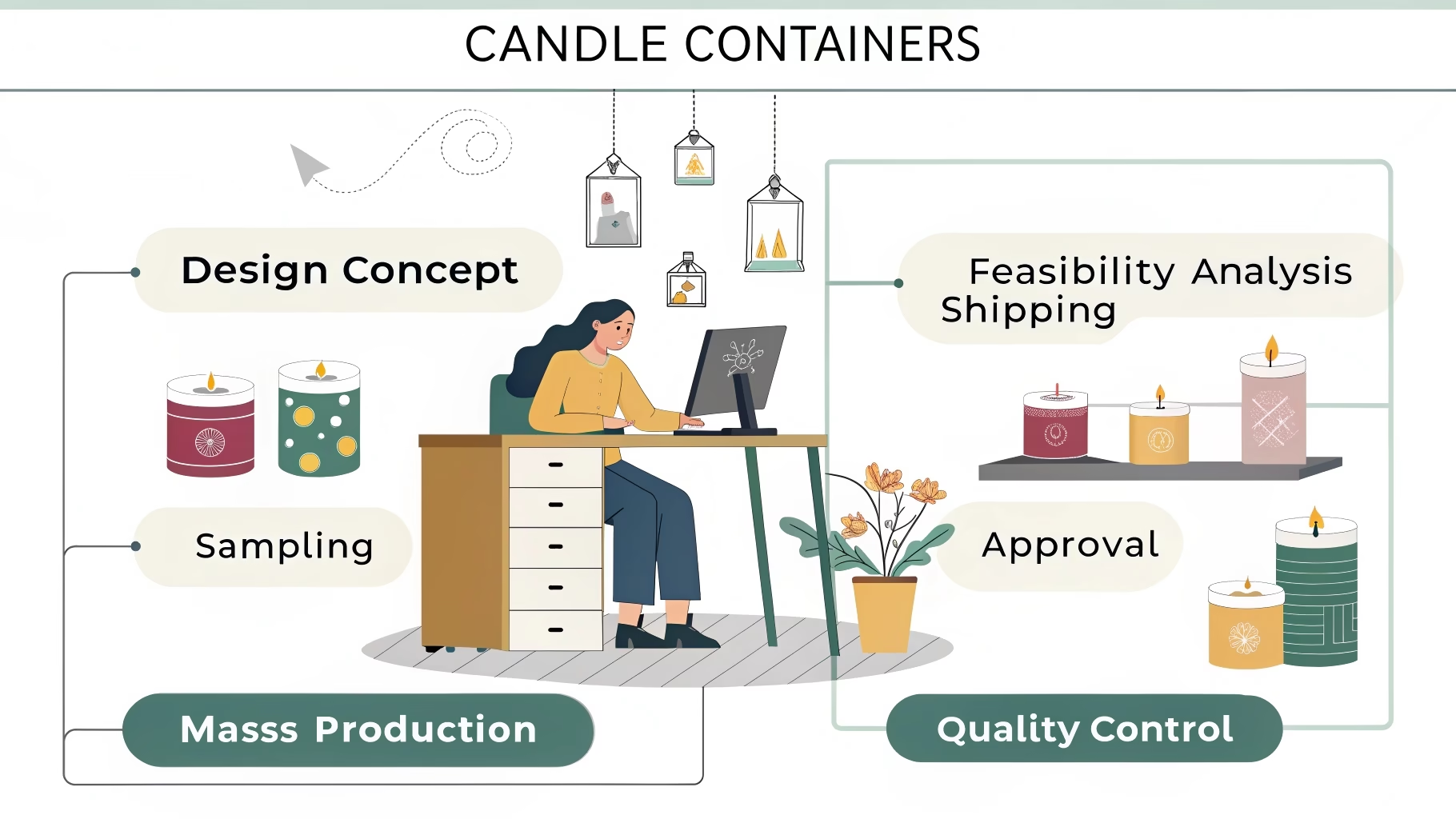

The steps clearly involve design concept, feasibility analysis, sampling, approval, mass production, quality control, and shipping1. Clearly following these stages ensures customized products meet your brand expectations.

Clear Step-by-Step Customization Guide

Detailed Steps for Custom Candle Containers

- Design Concept: Clearly define your vision and requirements.

- Feasibility Analysis: Evaluate materials, production methods, and costs.

- Sampling: Create prototypes for review.

- Approval: Adjust designs based on feedback clearly.

- Mass Production: Begin full-scale production after final approval.

- Quality Inspection: Thoroughly check all items for consistency.

- Shipping: Clearly plan safe, timely delivery.

Timeline for Each Step (Typical)

| Stage | Typical Duration | Important Actions |

|---|---|---|

| Concept & Feasibility | 3–7 days | Clearly specify requirements |

| Sampling | 7–14 days | Review & refine clearly |

| Production | 25–35 days | Follow detailed schedule |

| Inspection & Shipping | 5–10 days | Ensure quality & timely delivery |

Clearly following these steps leads to successful, high-quality customization.

How Do You Evaluate Potential Partners for Custom Candle Container Production?

You might feel unsure about selecting the right supplier. Let’s clearly discuss how to evaluate them.

Evaluate potential partners based on experience, production capabilities, communication clarity, quality control standards, flexibility with MOQs, and customer references2. Clearly assessing these factors ensures reliable, long-term cooperation.

Clearly Evaluate Production Partners

Factors to Evaluate Clearly

- Experience: Check proven history in candle containers.

- Capabilities: Confirm their ability to meet your customization needs.

- Communication: Quick responses, clear understanding.

- Quality Assurance: Verified standards, previous customer feedback.

- MOQ Flexibility: Ability to handle small or large orders clearly.

Partner Evaluation Checklist

| Evaluation Area | Questions to Ask Clearly |

|---|---|

| Experience | How many years producing similar products? |

| Quality Assurance | What inspections and certifications clearly exist? |

| Communication | How quickly do they respond to inquiries? |

| MOQ & Flexibility | Can they handle custom MOQs clearly? |

Clearly evaluating these helps ensure your customization project succeeds smoothly.

How Does Minimum Order Quantity (MOQ) Affect Your Customization Decisions?

You’re probably curious about MOQs and their impacts. I’ll clearly break this down.

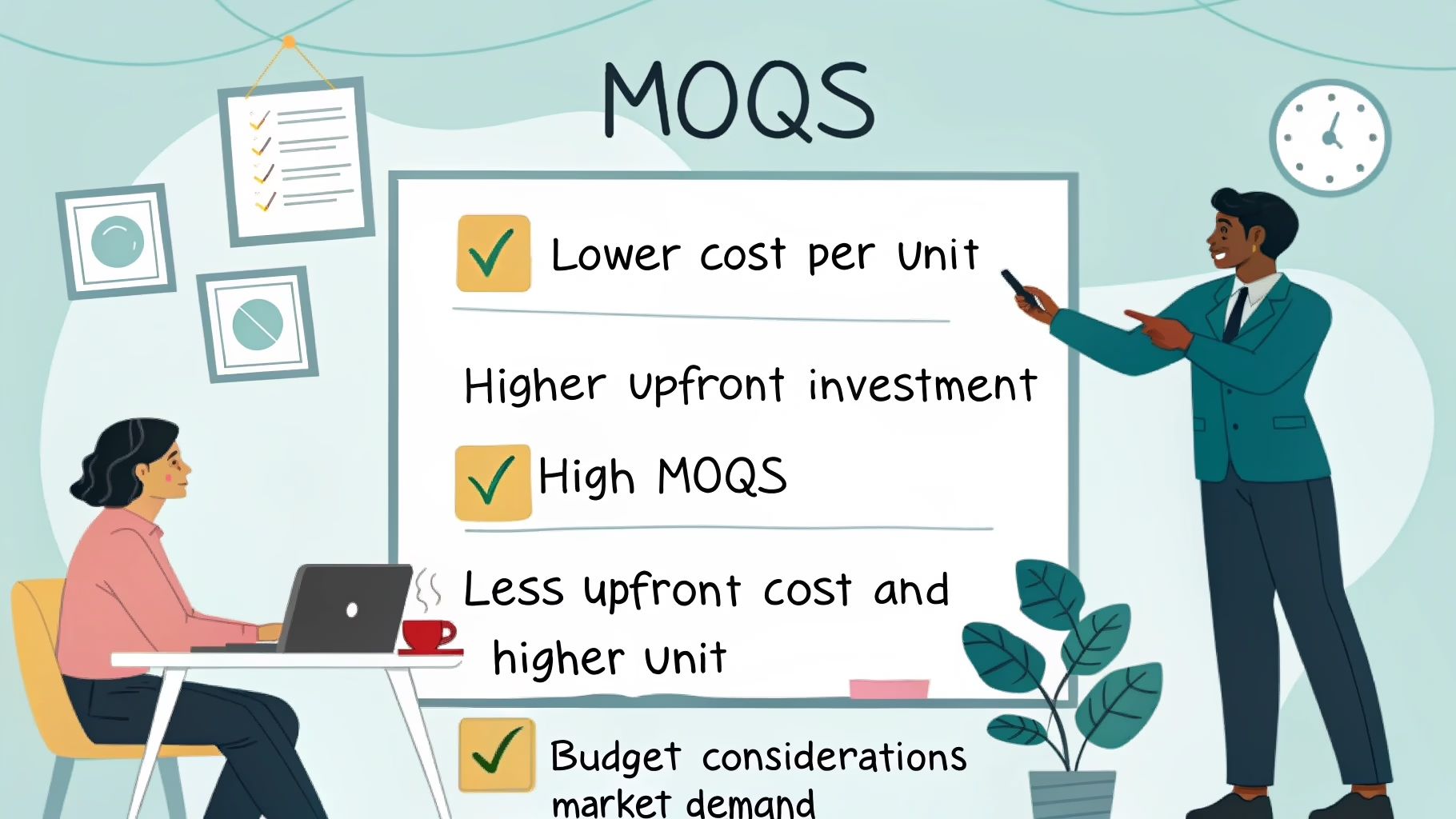

Minimum Order Quantity3 directly affects customization costs, flexibility, and product availability. Higher MOQs reduce unit costs but require more investment; lower MOQs offer flexibility but higher per-unit prices. Clearly consider your market needs.

Clearly Understanding MOQ Impact

Benefits and Challenges of Different MOQs

| MOQ Level | Benefits Clearly Explained | Challenges Clearly Stated |

|---|---|---|

| High MOQ | Lower cost per unit, consistent supply | Large upfront investment |

| Low MOQ | Less upfront cost, flexibility | Higher unit costs, limited customization options |

Tips for Deciding MOQ Clearly

- Budget: Clearly understand your available investment.

- Market Demand: Estimate clearly how many you can sell.

- Risk Tolerance: Decide clearly if you prefer lower risk (low MOQ) or lower unit cost (high MOQ).

Clearly understanding MOQs helps you make informed, cost-effective decisions.

What Strategies Ensure Quality and Consistency in Custom Candle Container Production?

You might worry about product quality and consistency. Let’s clearly explore strategies to ensure this.

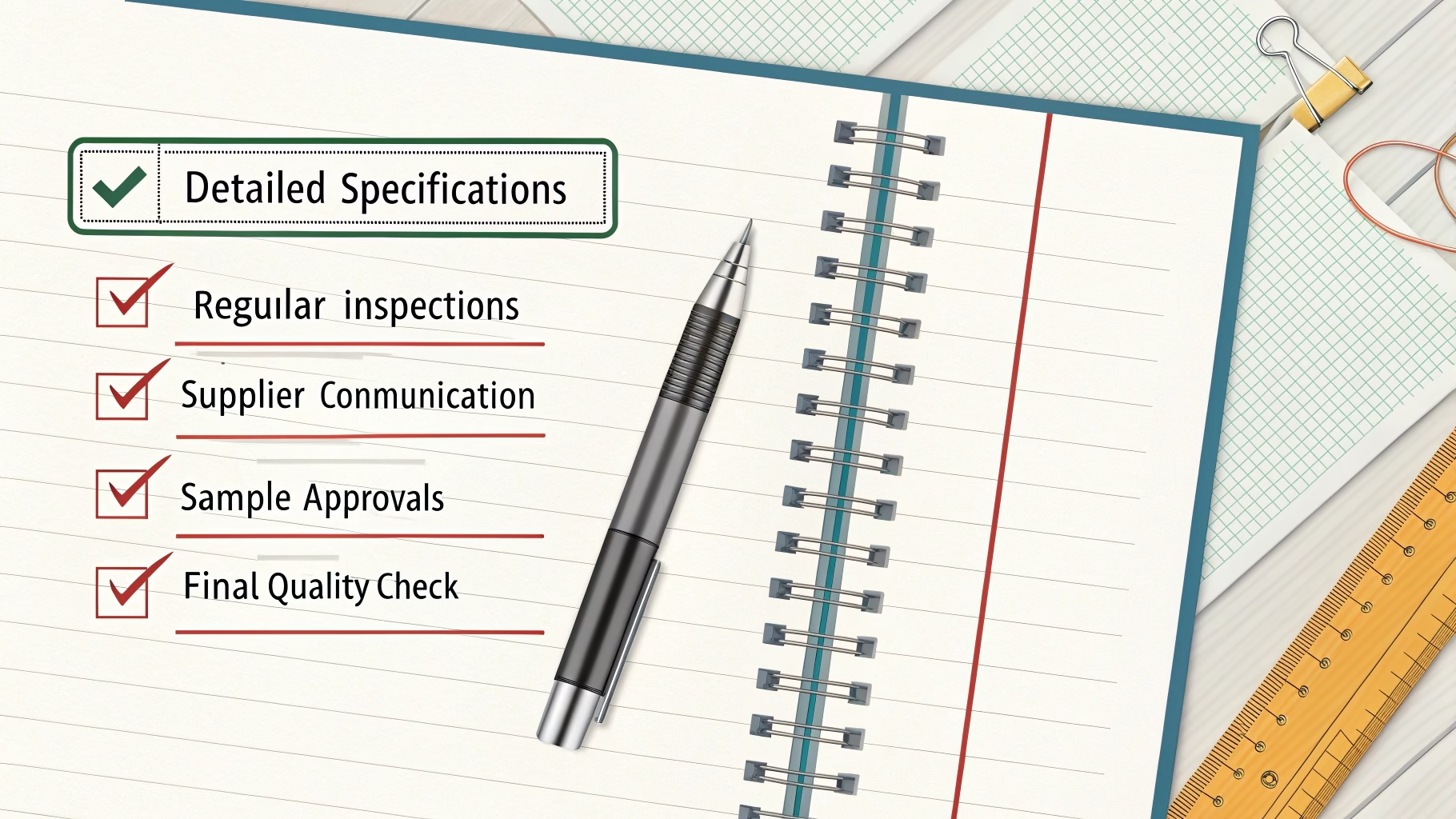

Ensure quality and consistency4 clearly through detailed specifications, regular inspections, effective supplier communication, sample approvals, and strong quality control processes. Clearly following these steps guarantees product excellence and brand reliability.

Clear Strategies for Quality Assurance

Essential Quality Strategies Clearly Outlined

- Detailed Specifications: Clearly document material, color, size, and finish requirements.

- Regular Inspections: Conduct inspections at multiple production stages.

- Supplier Communication: Maintain clear, ongoing communication to resolve issues early.

- Sample Approvals: Thoroughly inspect and approve samples before full production.

- Final Quality Check: Ensure each product meets agreed specifications before shipping.

Quality Control Checklist Example

| Quality Check Area | Action Steps Clearly Stated |

|---|---|

| Materials | Verify materials match agreed specs |

| Dimensions | Measure carefully against approved sample |

| Finish & Color | Visually inspect for defects or variations |

| Packaging | Confirm secure, damage-free packaging |

Clearly implementing these strategies ensures consistent, high-quality production.

Conclusion

Clearly understanding customization steps, evaluating production partners, managing MOQs, and ensuring quality guarantees success. Clearly following this process helps your high-end candle brand thrive and satisfy customers effectively.

-

explanation for the source. A detailed breakdown from Packaging Digest on how to manage packaging and product development stages from design to quality control. ↩

-

explanation for the source. Forbes Business Council article explaining key criteria for selecting a trustworthy manufacturer, relevant for product-based businesses. ↩

-

explanation for the source. Shopify’s blog post clearly explains what MOQ is and how it impacts production cost, flexibility, and risk. ↩

-

explanation for the source. QualityInspection.org shares a practical quality control plan template that applies to manufacturing industries, including home decor and candle products. ↩